Learn how to efficiently manage and reduce waste at your facility in just 12 weeks

Get 3 Months of Our €1,500 Waste Management Software—FREE!

How? Simply book a consultation and get it free!

Michal Malik

Waste Management Expert

87+

countries

500+

smart waste projects

40k+

active users

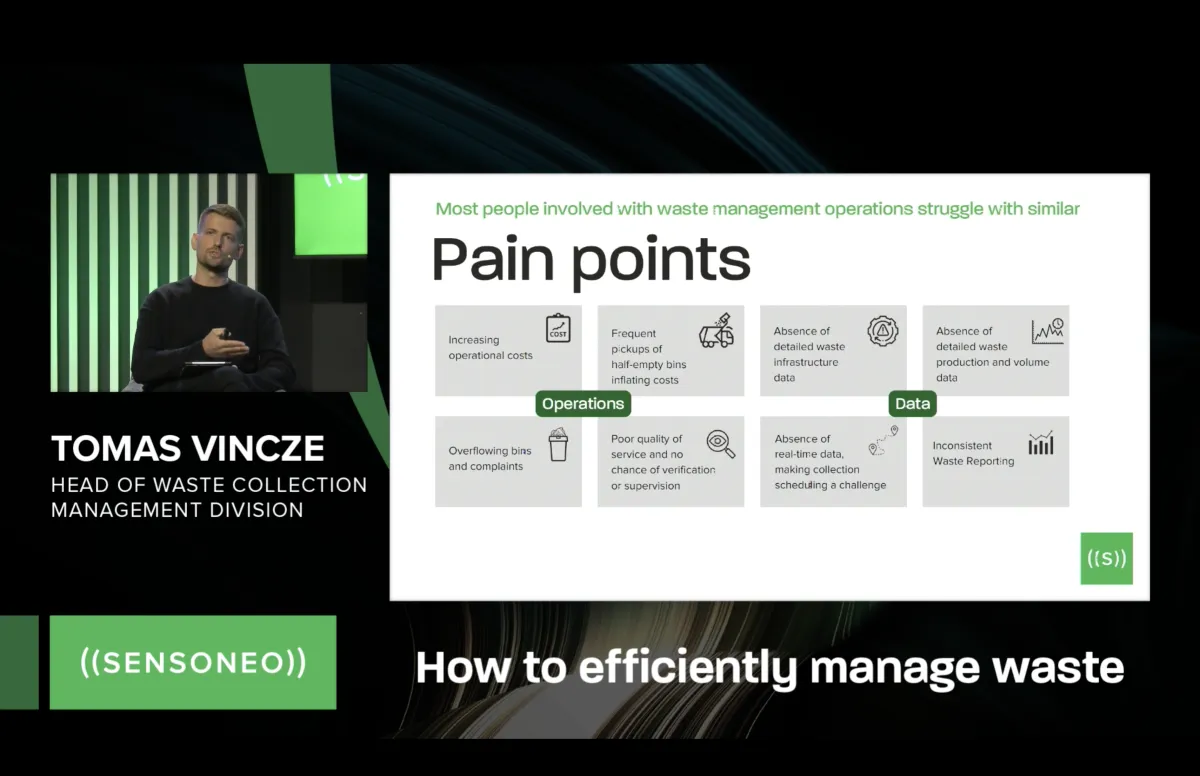

Book a consultation now if you’re facing these challenges:

Inefficient Waste Processes

Outdated waste collection systems increase downtime and drive up operational costs caused by waste collection delays

High Collection Costs

Frequent collections of half-empty bins waste resources. Smart scheduling can drastically cut costs and improve efficiency

Contaminated Waste Streams

No possibility to verify hauler services or track missed pickups, leading to inefficiencies

Limited Data Visibility

A lack of actionable waste data allows inefficiencies to go unnoticed, KPIs to be missed, and sustainability goals to remain out of reach

Third-Party Collector Accountability

No way to verify external waste collectors' work results in overspending and unreliable tracking

Sustainability & ESG Reporting

Without accurate reporting, it’s nearly impossible to hit zero waste goals or align with regulatory demands

GET OUR WEBINAR RECORDING ON MANUFACTURING WASTE MANAGEMENT

Our waste management experts have prepared an insightful webinar

for professionals in the manufacturing waste management

IN OUR WEBINAR, YOU WILL LEARN:

How data is shaping 2025 waste management standards

Cost-saving strategies for waste optimization

Best practices in circularity and waste diversion

Real-world success stories from manufacturing leaders

Why you should book consultation with our expert?

Before consultation

you are struggling with:

Disrupted production flow

High collection costs

Contaminated waste streams

Poor data visibility

No waste collector accountability

Missed sustainability & ESG goals

After consultation

you will know how to:

Optimized waste processes

Lower collection costs

Higher recycling rates

Actionable waste data

Transparent waste collector operations

Accurate sustainability reporting

SAY YES TO A DATA-DRIVEN MANUFACTURING WASTE MANAGEMENT

Why us?

Providing you with precision waste tracking

Track waste at every stage of production, from individual lines to facility-wide operations, with data insights that empower better decision-making.

Boosting your waste reduction strategies

Our real-time tracking and contamination analysis pinpoint waste hotspots, showing exactly where to focus your waste reduction initiatives for maximum impact.

Unlocking sustainability that delivers results

Achieve sustainability KPIs by improving waste diversion, reducing contamination, and aligning your operation with goals. Sensoneo helps you cut costs and exceed ESG standards.

Enabling control with data-driven insights

Monitor your waste infrastructure with precision, controlling third-party collectors. Just-in-time collection cuts FTE costs by reducing pickups and optimizing routes to align with your goals and budget.

"Using smart sensors we are able to guarantee daily collection of volumes we need for a smooth logistics process – and it takes us fewer hours and less km than before."

Juraj Kunak, CEO and Founder of Ekocharita

ABOUT SENSONEO

Global leader in

smart waste solutions

End-to-end smart waste management solutions for manufacturing companies

In-house R&D

Enterprise-grade hardware, software and analytics solutions

Deployment of largest smart waste project worldwide:

11 000 sensors for Madrid municipality

HIGHLIGHTS OF OUR WORK

How we helped optimize waste management

Sensoneo digitized waste collection for a rolling bearings manufacturer Schaeffler with smart sensors, boosting efficiency and preventing overflowing bins.

Managing 490,000 kg of waste across 33 containers, and 17 waste types, the solution saved 42,086 kg of CO2 while enhancing reporting and streamlining external collector management.

A European fulfillment center optimized waste management through our smart waste management, cutting FTE positions from 7 to 4 and saving €85,207 per site annually.

By digitizing waste collection, the facility achieved a 99.82% waste diversion rate and reduced CO₂ emissions by 35,754 kg per facility.

Automotive Manufacturer

A leading truck manufacturer partnered with Sensoneo to digitize their waste management, starting with a pilot monitoring 204 bins across their facility and managing 6 waste types.

Impressed by the improved efficiency and waste tracking, they plan to extend our solution across their entire factory.

Tractor factory in Germany implemented Sensoneo's Factory Waste Management solution, utilizing our platform to optimize waste management.

This led to significant cost reductions, improved operational efficiency, and enhanced sustainability efforts.

Sensoneo digitized waste collection for a rolling bearings manufacturer Schaeffler with smart sensors, boosting efficiency and preventing overflowing bins.

Managing 490,000 kg of waste across 33 containers, and 17 waste types, the solution saved 42,086 kg of CO2 while enhancing reporting and streamlining external collector management.

A European fulfillment center optimized waste management through our smart waste management, cutting FTE positions from 7 to 4 and saving €85,207 per site annually.

By digitizing waste collection, the facility achieved a 99.82% waste diversion rate and reduced CO₂ emissions by 35,754 kg per facility.

Automotive Manufacturer

A leading truck manufacturer partnered with Sensoneo to digitize their waste management, starting with a pilot monitoring 204 bins across their facility and managing 6 waste types.

Impressed by the improved efficiency and waste tracking, they plan to extend our solution across their entire factory.

Tractor factory in Germany implemented Sensoneo's Factory Waste Management solution, utilizing our platform to optimize waste management.

This led to significant cost reductions, improved operational efficiency, and enhanced sustainability efforts.

Cost Calculator

(Click the button in the bottom right to open the Cost Calculator in full-screen mode)

(Open with a desktop browser to access the Cost Calculator)

2024 SENSONEO All rights reserved